Shotrun Cleaning for Inspection

Shotrun Cleaning for Inspection Method outline

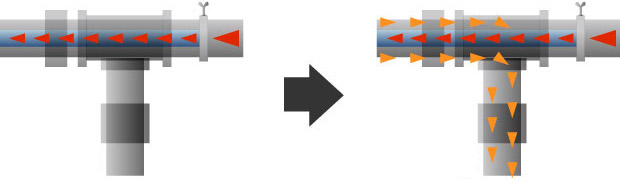

In this cleaning method, both the inside and outside of the tubing is simultaneously cleaned.

Conventional Cleaning Methods:

In conventional cleaning methods such as wire brush, jet wash, acid cleaning and shot blasting, first a sample tube is selected and removed for inspection. Secondly, the tube is cut in half lengthwise. Both the inside and outside of both pieces of tube is polished to reveal the pipe’s condition. Pipe cleaning is actually performed twice. Lastly the tube is inspected for thickness and condition.

Shot-Run Cleaning Method:

In the Shot-Run Method, the entire tube is removed and polished to reveal the pipe condition. Then it is cut in half lengthwise and inspected. Because the order of operations is different, the Shot-Run Cleaning Method saves time and money as the tube is only cleaned once, not twice, as in conventional cleaning methods.

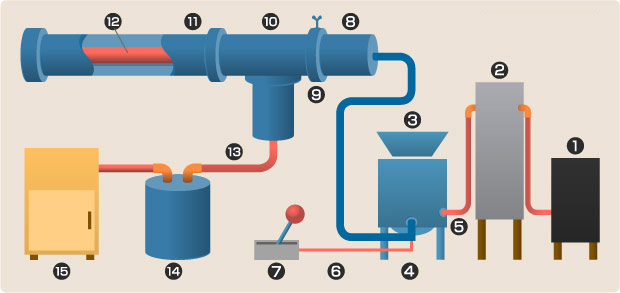

The target tube is removed and placed in the Shot-Run cleaning case. The cleaning nozzle is then inserted into the tube. Next cleaning operations are started and abrasive is sent through the inside of the tube. When it reaches the end of the tube it returns to the insertion point and is then circulated to polish the outside of the tube. Finally all abrasive is deposited in a recovery system.

- Air compressor

- Air dryer

- Cleaning unit

- Hose joint

- Diagram valve

- Remote controller cable

- Remote control switch

- Nozzle

- Adopter with holder

- Abrasive collection nozzle

- Shot-run cleaning case

- Target tube(Tube to be polished)

- Abrasive collection duct

- Abrasive recovery unit

- Dust collector

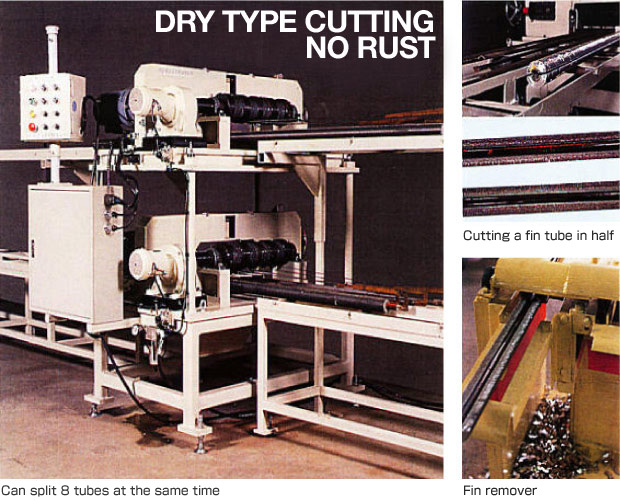

Horizontal Pipe Cutting Machine Patent No. 25/6936

Accurate inspection of the pipe’s condition is possible by cutting the pipe lengthwise after all scales and deposits have been removed.

Characteristics of the Horizontal Split Machine

It has the capacity to simultaneously cut 8 tubes with a 6 meter length longitudinally in only 5 minutes.

Pipes with diameters ranging from 16mm to 60mm can be cut.

It can cut B, TF, STB and STU type tubing.

It can also easily remove fins and cut fin tubing.

This is a dry cutting process thus unnecessary chemicals and water are not required.

This machine will not damage the outside of the tube.

Because the machine’s blade is a mere 1.2mm, material loss is minimal.