U-PIG METHOD

PIG METHOD

The pig method is useful for cleaning the inside of parts of long distance piping arrangements and of large sized piping arrangements in which mainly petroleum flows or is delivered. In particular, the UNIPEC U-Pig can successfully remove very hard scales and high viscosity substances from inside piping arrangements and lines which were impossible to remove before now using conventional methods. We have further strengthened our products by adding urethane rubber and other advanced materials to handle removal of scales and other contaminants in practically any conceivable piping arrangement. We currently manufacture more than 30 kinds of products including solvent proof and heat proof products.

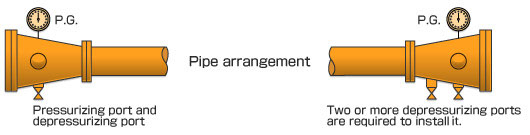

METHOD OUTLINE

| 1)Tees |  |

| 2)Bend | Short and long. Return pass. Flat bends and thread bend cautions. |

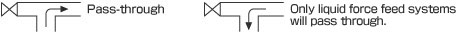

| 3)Reducer | Soft pigs pass through. Hard pigs may not pass through. |

| 4)Value | Gate and ball valves are passable while others are not. Chuck valves become passable by demounting a plate. |

| 5)Flowmeter | Doesn't pass through. |

| 6)Thermometer | Remove them and plug the existing hole. |

| 7)Downward Expansion | It's necessary to pay attention to bellow types and inner cylinder attachments. |

| 8)Joint | It's necessary to watch for spewing from the inside flange gasket, large sized weld sagging and poor pressure proofing. |

|  |  |

|---|---|---|

|

A.)Pig advances half way:

Depressurized feeding towards a branch pipe. B.)Main pipe was broken and thus depressurized. |

A) Pig advances half way: The pig advances towards a branch pipe and pressure at the force feeding point causes source leaks. B) Pig was worn out or broken. |

|

A) Stoppage is caused by lengthy foreign matter and projectiles. B) Stoppage is caused by excessive scales and deposits. |

A) Shortage of pressure or volume at force feeding point. B) If the launcher pressure gauge amplifies vertically, it means the pig will advance smoothly. |

Adjust the pressure and flow rate as follows:

Liquid force feed - 0.5 m/sec - 1m/sec

Air force feed - 1-2 m/sec

Pressure can be calculated with the following formula:

(Pressure loss at in tube fluid) + (Pig frictional pressure loss at 0.3 - 2kg/cm²)